Top Quality Pressure Sensors Manufacturers and Suppliers in China - Reliable Options

At Linyi Weiman Import and Export Co., LTD., we provide high-quality pressure sensors specifically designed for a range of industrial applications. With years of manufacturing expertise, we cater to the unique requirements of B2B purchasers seeking dependable and precise measurement tools. Our pressure sensors are engineered for exceptional performance and durability, making them ideal for wholesale distribution. Committed to maintaining rigorous quality standards, our factory-direct pricing ensures you receive outstanding value without compromising on quality. Serving sectors such as automotive, aerospace, and manufacturing, our sensors are engineered to meet diverse operational demands. Partner with us to benefit from efficient communication, timely delivery, and exceptional customer service, enhancing your product range and meeting your clients' needs effectively.Practical Strategies for Pressure Senson Factory-Direct Excellence Ahead of the Curve

In the competitive world of heavy construction equipment, staying ahead of the curve requires not only top-quality products but also a commitment to operational excellence. Global buyers seeking to source pressure sensors for their machinery can benefit from practical strategies that enhance product quality and supply chain efficiency. By prioritizing factory-direct relationships, businesses can ensure they are obtaining the most reliable sensors directly from manufacturers, thus reducing the risks associated with intermediaries. Establishing solid partnerships with factories enables buyers to have real-time access to product updates and innovations that can drive performance. Moreover, leveraging advanced technologies in manufacturing and quality control is essential. By employing state-of-the-art techniques and rigorous testing procedures, manufacturers can guarantee that their pressure sensors meet the highest industry standards—crucial for minimizing downtime and optimizing equipment performance. Buyers should consider suppliers that are not only equipped with cutting-edge facilities but also demonstrate a clear commitment to continuous improvement and customer satisfaction. Lastly, understanding market trends and customer expectations is critical for maintaining a competitive edge. Vendors who actively engage with global markets can identify emerging needs and tailor their offerings accordingly. This adaptability, combined with a focus on product excellence, positions suppliers to not only meet current demands but also to anticipate the future needs of the construction industry, ultimately fostering long-term partnerships with global procurement professionals.

Practical Strategies for Pressure Sensor Factory-Direct Excellence Ahead of the Curve

| Strategy | Description | Expected Outcome | Implementation Timeframe |

|---|---|---|---|

| Lean Manufacturing | Implementing practices to minimize waste and enhance efficiency in production. | Reduced costs and improved throughput. | 3-6 months |

| Quality Assurance Programs | Regular inspection processes to ensure product quality meets standards. | Increase in customer satisfaction and lower return rates. | Ongoing |

| Employee Training | Ongoing training programs to enhance worker skills and knowledge. | Improved employee performance and productivity. | Monthly sessions |

| Data-Driven Decisions | Use analytical tools to assess production data and drive decision-making. | Enhanced operational efficiency and smart investment in resources. | 3 months to implement tools |

| Supply Chain Optimization | Streamlining supply chain processes to improve delivery times and cost-efficiency. | Faster production cycles and reduced inventory costs. | 6-12 months |

Cutting-Edge Pressure Senson Outperforms the Competition Winning in 2025

W

William Harris

Very happy with my purchase! The quality is outstanding, and the support team is very efficient.

28 May 2025

A

Avery Thompson

Impressive quality! The customer service team demonstrated great expertise and support.

07 May 2025

L

Lily Ward

Beyond satisfied! The quality is impressive and support staff was efficient and friendly.

18 June 2025

L

Leo Reed

Amazing quality! The customer service staff were exceptional in addressing my needs.

08 June 2025

K

Kylie Price

The quality is evident! The after-sales team was professional and accommodating.

28 May 2025

A

Adam Hayes

Truly impressed! Quality and after-sales service are both exceptional.

03 July 2025

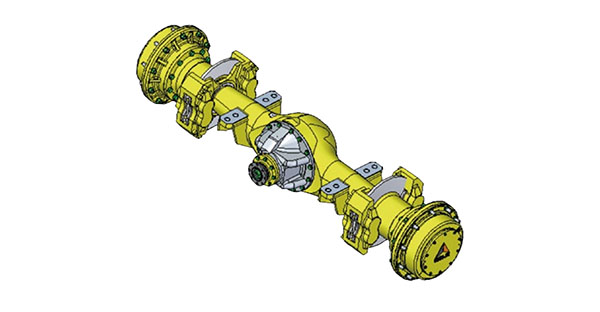

Wheel Loader

Wheel Loader  Excavator

Excavator  Motor Grader

Motor Grader  Backhoe Loader

Backhoe Loader  Road Roller

Road Roller  Spare Parts

Spare Parts