The temperature has dropped sharply, please put on more clothes to keep you and your "old friend" warm in time!

Autumn arrived overnight, and the chill winds have already arrived. When the first withered leaf frosts in the morning light, and when our breath turns to white mist in the air, we know—autumn has arrived.

In this abruptly cold season, I want to send my first warmth to everyone who remains committed to their work: Please remember to dress warmly and protect your health. Your hands support not only projects, but also the hopes of every family.

People need to dress warmly, and so do the "iron warriors" who work alongside us—excavators, loaders, and other construction equipment. Low temperatures not only test our resolve, but also the performance and endurance of these "old friends."

To this end, SDLG has prepared a "Winter Maintenance Guide for Construction Machinery" to help your equipment lay a solid foundation for efficient operation next year, providing comprehensive care for your "old friend" and ensuring a safe winter!

01 Oil System: Maintenance of the Equipment's "Blood"

Low temperatures significantly increase oil viscosity, affecting fluidity and lubrication. It's recommended to promptly replace with low-viscosity winter oil to avoid starting difficulties and component wear caused by reduced fluidity. Also, check the hydraulic oil level and select a hydraulic oil type suitable for the local minimum temperature to ensure the hydraulic system remains responsive in cold conditions. For fuel systems, switch to winter diesel to effectively prevent oil line blockage caused by wax formation at low temperatures. It's recommended to top up the fuel tank at the end of each day's operation to minimize condensation on the tank walls due to the temperature swing between day and night.

02 Cooling System: Antifreeze is Key

Antifreeze is the engine's "guardian" in winter. Always check its freezing point to ensure it's below the local minimum temperature, and refill or replace it promptly. It not only prevents coolant from freezing and cracking the radiator and engine block, but also provides important protection against boiling and corrosion. Also, clean the radiator and radiator crevices to prevent debris and dust from affecting heat dissipation, ensuring the entire temperature control system operates properly in winter.

03 Cooling System: Freeze Protection is Key

Low temperatures significantly reduce battery capacity. Keep the battery terminals clean and securely connected to prevent leakage. If the equipment will be parked for an extended period, it is recommended that the batteries be removed and stored in a warm, dry room to extend their lifespan. Also, check the starter and generator wiring for reliable connections and remove any accumulated dust to ensure sufficient starting power even on cold mornings.

04 Key Components: The Secret is in the Details

Clean or replace the air filter regularly to prevent dust accumulation from affecting engine intake efficiency, leading to reduced power and fuel waste. Carefully inspect the chassis, boom, bucket, and other structural components for signs of cracking or rust. Cold weather can reduce metal toughness, and a thorough inspection can effectively eliminate safety hazards. Additionally, apply the appropriate grade of winter grease to all moving parts that require lubrication, such as pins and bearings, to ensure smooth operation even in low temperatures.

05 Storage and Operation: Good Habits Extend Equipment Life

When conditions permit, park the equipment in a sheltered location to give your equipment a warm "home." After starting the equipment, always allow it to idle for 5-10 minutes to warm up key components such as the engine and hydraulic oil. Only operate it at full capacity after reaching ideal operating temperatures. Initial operation should be gentle and smooth to allow the hydraulic oil and other fluids to fully circulate and heat within the system, avoiding shock and wear caused by violent movements.

Wheel Loader

Wheel Loader

Excavator

Excavator

Motor Grader

Motor Grader

Backhoe Loader

Backhoe Loader

Road Roller

Road Roller

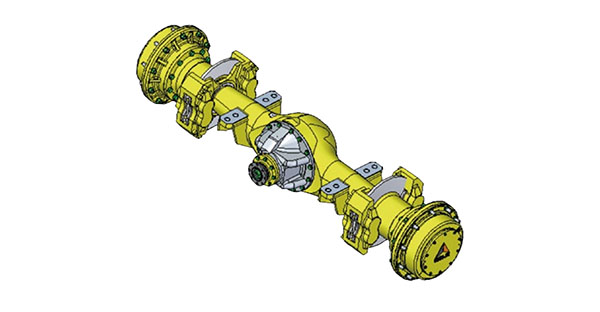

Spare Parts

Spare Parts