Premium Injection Nozzle Tubes from Top Suppliers & Manufacturers - High Quality Assured

When sourcing high-quality Injection Nozzle Tubes, it is essential to partner with reliable wholesale suppliers. Linyi Weiman Import and Export Co., LTD., is a reputable manufacturer committed to precision and quality in our products. Our Injection Nozzle Tubes are designed for optimal performance and durability in industrial applications. We ensure that our materials are sourced from trusted factories, adhering to stringent quality standards. Offering competitive pricing and bulk purchasing options, we cater to distributors and businesses aiming to enhance their operations. With a focus on exceptional product quality and dedicated customer service, we strive to make your purchasing experience seamless and efficient. Trust us as your partner in the injection nozzle tube market for mutual success.Practical Strategies for Injection Nozzle Tube From Concept to Delivery Now Trending

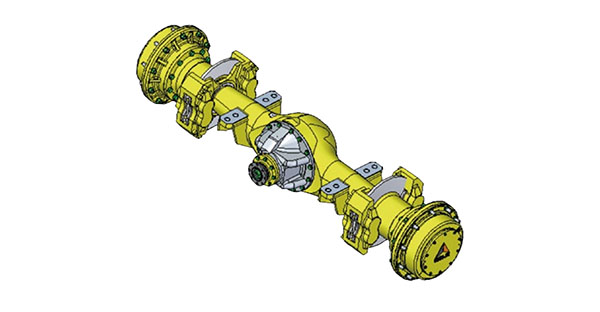

In the ever-evolving construction equipment industry, the demand for high-quality components plays a critical role in ensuring efficient operations. One of the standout components is the injection nozzle tube, a vital part of various machinery such as excavators and loaders. As the global market navigates complexities, understanding practical strategies for sourcing and delivering these components is essential for procurement managers. From concept to delivery, the process begins with identifying reliable suppliers that adhere to stringent quality standards. Prioritizing partnerships with manufacturers who leverage advanced production techniques and quality control measures can significantly reduce lead times and improve trust in the supply chain. Additionally, it is crucial to engage with suppliers who are adept at adapting to market trends, ensuring that the latest specifications and innovations are included in their offerings. This proactive approach not only enhances operational efficiency but also aligns with the purchasing strategies of globally-minded companies. Furthermore, streamlining communication and establishing clear expectations with suppliers enhances collaboration and minimizes misunderstandings. Utilizing technology, such as online platforms and software solutions, can facilitate real-time updates on order status and inventory availability. By integrating these practical strategies, procurement professionals can successfully navigate the complexities of sourcing injection nozzle tubes, ensuring that their construction projects remain on time and within budget while utilizing cutting-edge equipment tailored to their specific needs.

Practical Strategies for Injection Nozzle Tube From Concept to Delivery Now Trending

| Stage | Key Actions | Expected Outcomes | Timeframe | Resources Needed |

|---|---|---|---|---|

| Concept Development | Market Research, Feasibility Study | Validated Concept, Estimated Market Demand | 1-2 Months | Survey Tools, Research Reports |

| Design Phase | 3D Modeling, Prototyping | Prototype Ready for Testing | 2-3 Months | Design Software, Materials for Prototype |

| Testing Phase | Quality Assurance Testing, User Feedback | Refined Product Design, User-Centric Improvements | 1-2 Months | Testing Equipment, User Panels |

| Production Preparation | Supplier Selection, Production Planning | Established Supply Chain, Production Schedule | 1 Month | Supplier Contracts, Production Resources |

| Market Launch | Marketing Campaign, Distribution Setup | Product Availability, Market Penetration | 1 Month | Marketing Budget, Distribution Channels |

The Clear Choice of Injection Nozzle Tube Manufacturers You Can Rely On Is The Best

D

Daniel Johnson

Excellent purchase! The support personnel displayed impressive expertise in resolving my inquiries.

04 July 2025

L

Liam Clark

I highly recommend this product. The quality is fantastic and customer care is top-tier!

22 May 2025

C

Charlotte Lewis

The craftsmanship is excellent! Customer support was quick to respond and very friendly.

28 June 2025

E

Ella Rodriguez

This item is fantastic! The after-sales support was superior and very knowledgeable.

16 June 2025

M

Mason Rodriguez

This is a remarkable product! The customer service was very attentive and knowledgeable.

16 May 2025

C

Cole Hughes

Outstanding product! The service team was very professional and quick to assist.

01 June 2025

Wheel Loader

Wheel Loader  Excavator

Excavator  Motor Grader

Motor Grader  Backhoe Loader

Backhoe Loader  Road Roller

Road Roller  Spare Parts

Spare Parts