Reliable Volvo Construction Machinery Suppliers for Wholesale Solutions

Linyi Weiman Import and Export Co., LTD. offers a diverse range of high-quality Volvo construction machinery tailored for various construction projects. As an authorized manufacturer and distributor, we provide an extensive lineup that includes excavators, wheel loaders, articulated haulers, road machinery, and compact equipment. Known for their durability, efficiency, and productivity, our Volvo machines are built to excel in both small-scale residential and large-scale commercial applications. In addition to providing top-tier machinery, we are committed to offering exceptional after-sales service and support, ensuring our customers get the most out of their equipment. Trust Linyi Weiman Import and Export Co., LTD. for your Volvo construction machinery needs and elevate the performance of your construction projects.Best Strategies For Volvo Construction Machinery Manufacturer Products Guarantees Peak Performance

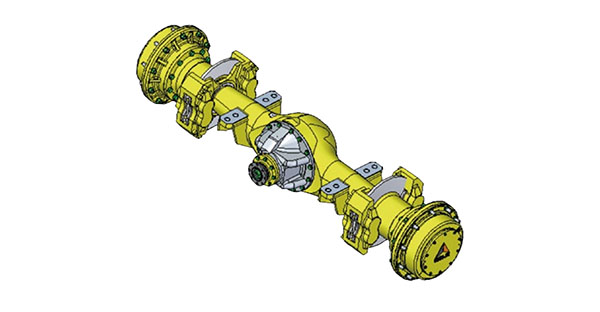

When it comes to ensuring peak performance for Volvo construction machinery products, understanding the best strategies is essential for manufacturers and global buyers alike. At Linyi Weiman Import and Export Co., LTD, located in the heart of Shandong Province, we pride ourselves on being a leading supplier of heavy construction equipment, offering a diverse range of machinery including wheel loaders, luxury mini loaders, backhoe loaders, skid steer loaders, excavators, and motor graders. To maximize the performance of Volvo construction equipment, maintenance is key. Regular inspections and servicing can prevent costly downtime and ensure machinery operates at optimal efficiency. Utilizing genuine parts and professional services tailored to Volvo specifications is crucial, as it guarantees not just longevity but also compliance with quality standards. Moreover, leveraging advanced technology such as telematics can provide valuable insights into equipment health and performance metrics, allowing for timely interventions and operational improvements. Education and training also play a significant role in performance optimization. By investing in operator training programs, companies can cultivate skilled personnel who understand the intricacies of Volvo equipment and can exECUte their tasks effectively. In conclusion, by adhering to these strategies—consistent maintenance, using high-quality parts, and providing proper training—manufacturers can ensure that Volvo construction machinery performs at its best, ultimately meeting the demands and expectations of global buyers in the competitive construction market.

Best Strategies For Construction Machinery Manufacturer Products Guarantees Peak Performance

| Strategy | Description | Expected Outcome | Implementation Timeframe |

|---|---|---|---|

| Regular Maintenance Schedule | Establish a structured maintenance plan to prevent breakdowns. | Improved equipment lifespan and reliability. | Ongoing |

| Operator Training Programs | Provide comprehensive training for operators on machinery usage. | Increased efficiency and reduced accidents. | 6 Months |

| Utilization of Quality Spare Parts | Replace parts with high-quality, manufacturer-recommended options. | Enhanced performance and durability of machinery. | As Needed |

| Implementation of IoT Technology | Integrate Internet of Things for real-time monitoring of machines. | Proactive maintenance and performance optimization. | 1 Year |

| Feedback Mechanism for Users | Create channels for users to report issues and suggestions. | Continuous improvement in machinery design and performance. | Ongoing |

Exploring Volvo Construction Machinery Manufacturer Sets the Industry Standard Application

A

Ava Martinez

Great product! After-sales team showed true professionalism and helped with all my queries.

12 May 2025

J

Jameson Taylor

Incredible item! The after-sales support staff was remarkable and very knowledgeable.

03 July 2025

C

Chloe Rogers

Impressive durability! The after-sales staff clearly knows their product very well.

11 May 2025

A

Alyssa Reed

Superb quality! The customer service team was quick to follow up on my questions.

16 May 2025

Z

Zachary Brooks

Superb quality! I appreciated the professionalism and expertise of the support staff.

03 June 2025

L

Luca Young

The quality of this product is impressive! The after-sales team was professional and very helpful.

17 June 2025

Wheel Loader

Wheel Loader  Excavator

Excavator  Motor Grader

Motor Grader  Backhoe Loader

Backhoe Loader  Road Roller

Road Roller  Spare Parts

Spare Parts