Wholesale Oil Piston Ring Supplier & Manufacturer for All Engine Applications

As a producer of premium oil piston rings, we recognize the vital role that reliability and performance play in machinery. Our offerings are meticulously crafted to comply with the stringent requirements of diverse engines, guaranteeing optimal sealing and minimized friction. By choosing our products, you align with a factory that emphasizes durability and efficiency, ensuring long-lasting solutions for your equipment.Exploring oil piston ring AppliCATion From Concept to Delivery

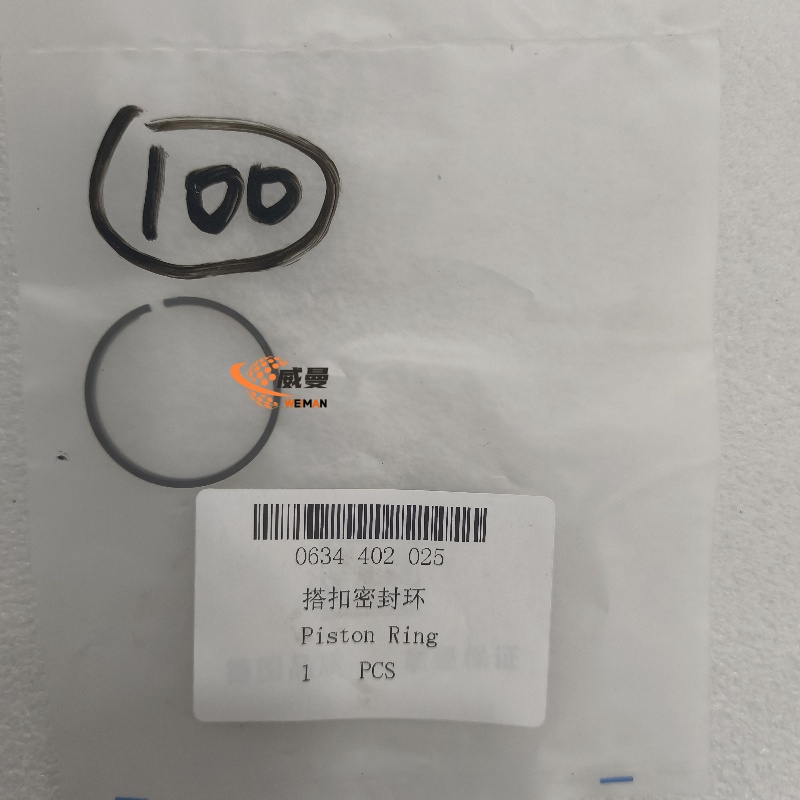

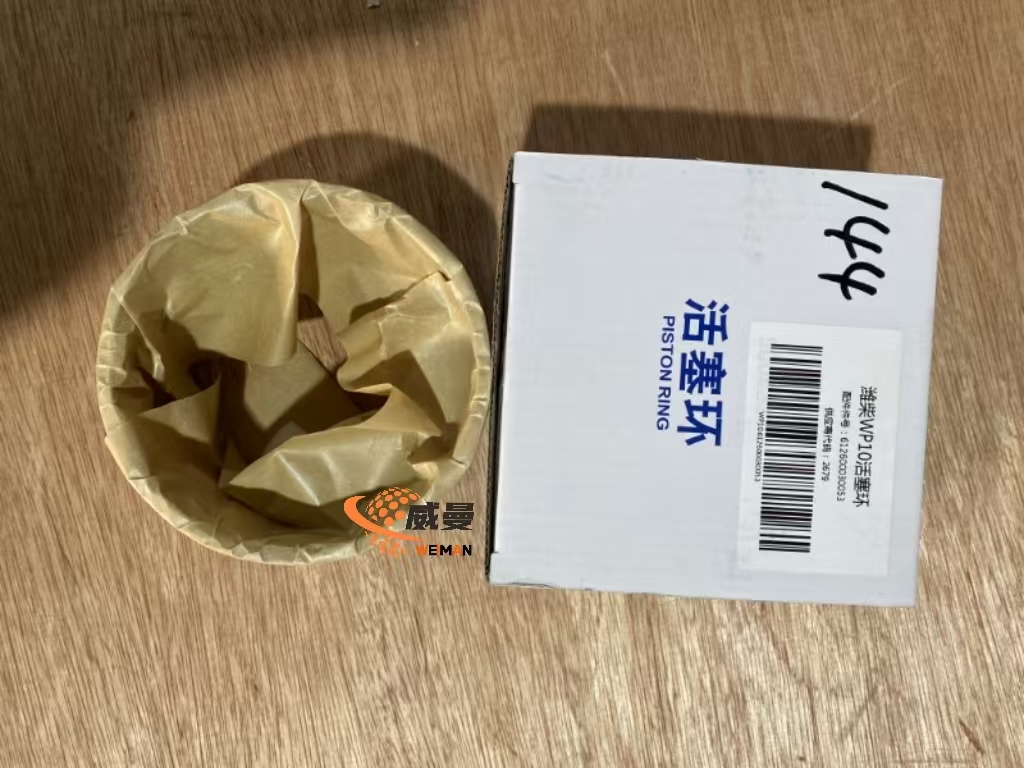

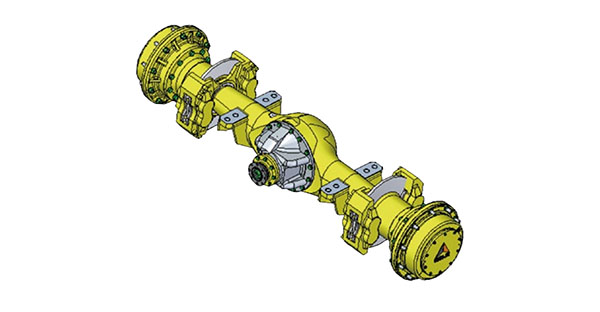

At Linyi Weiman Import and Export Co., LTD, we understand that efficient machinery relies heavily on each component's performance, particularly in heavy construction equipment. One key aspect that often goes unnoticed is the oil piston ring, a vital component in engines that ensures optimal performance and durability. This blog explores the application of oil piston rings from concept to delivery, shedding light on their significance in the construction machinery industry. Oil piston rings are engineered to maintain the oil film between the cylinder wall and piston while preventing oil from leaking into the combustion chamber. This intricate design is crucial for heavy equipment like wheel loaders, backhoe loaders, and excavators, where the demand for reliability and efficiency is paramount. At Weiman, we source high-quality piston rings that meet rigorous international standards, ensuring that our customers receive machinery that can withstand the toughest conditions on job sites worldwide. From the initial concept phase to the final delivery, our team is dedicated to providing seamless integration of oil piston rings in our machinery. We collaborate with trusted manufacturers and utilize advanced technology to optimize production processes, ensuring that we maintain a competitive edge in the global market. As the top professional construction equipment supplier in Shandong province, Weiman is committed to empowering our clients with reliable and innovative solutions that enhance productivity and efficiency in their operations. Partner with us to experience the difference that superior quality and professional service can make in your projects.

Exploring Oil Piston Ring Application From Concept to Delivery

| Application Area | Material | Coating | Manufacturing Process | Performance Metric |

|---|---|---|---|---|

| Automotive Engines | Cast Iron | Chrome Plating | CNC Machining | Wear Resistance (1000 hours) |

| Marine Engines | Aluminum Alloy | PTFE Coating | Forging | Temperature Tolerance (up to 200°C) |

| Industrial Compressors | Steel | Nitriding | Casting | Pressure Resistance (up to 20 bar) |

| Aviation Engines | Titanium Alloy | Ceramic Coating | 3D Printing | Fatigue Life (5000 cycles) |

| Locomotive Engines | Ductile Iron | Zinc Plating | Extrusion | Corrosion Resistance (1000 hours) |

How To Identify oil piston ring Pioneers in the Field For the Current Year

D

Daniel Johnson

Excellent purchase! The support personnel displayed impressive expertise in resolving my inquiries.

04 July 2025

C

Charlotte Lewis

The craftsmanship is excellent! Customer support was quick to respond and very friendly.

28 June 2025

L

Lily Ward

Beyond satisfied! The quality is impressive and support staff was efficient and friendly.

18 June 2025

C

Christopher Lee

Quality is unbeatable! The after-sales support team was friendly and very knowledgeable.

20 June 2025

M

Madeline Clarke

This item is fantastic! The support team answered all my questions promptly.

25 June 2025

C

Cora Foster

Very satisfied! The quality is excellent, and the support staff provided real expertise.

17 May 2025

Wheel Loader

Wheel Loader  Excavator

Excavator  Motor Grader

Motor Grader  Backhoe Loader

Backhoe Loader  Road Roller

Road Roller  Spare Parts

Spare Parts