Hard rock nemesis! The new generation of high-strength rock buckets has been launched, helping mine efficiency reach new heights.

In demanding applications such as mining, large-scale infrastructure construction, and rock crushing, bucket durability and efficiency are directly linked to project progress and cost control. Linyi Weiman Import and Export Co., Ltd. recently launched its latest series of high-strength, specialized rock buckets. With their revolutionary wear-resistant design, superior rock-breaking capabilities, and exceptionally long service life, these buckets provide the ultimate solution for extreme hard rock conditions, marking a new era in rock bucket technology.

Designed for tough tasks

Traditional general-purpose buckets wear rapidly when working with hard materials like granite, basalt, and quartzite. The tooth tips, lip, side plates, and even the bottom of the bucket are easily damaged and deformed, requiring frequent replacement and significantly impacting operational efficiency and increasing operating costs. Our new generation of rock buckets has been developed specifically to address this industry pain point.

Core technological innovation creates an indestructible bucket.

1. Premium wear-resistant materials: Key load-bearing areas of the bucket (such as the lip, side cutters, tooth adapter, and front bucket bottom) are manufactured from imported ultra-high-strength wear-resistant steel plates such as HARDOX and JFE-EH series. Their hardness and impact toughness far exceed those of ordinary steel, effectively resisting the intense wear and impact of hard rock.

2. Reinforced structural design: The overall structure has been optimized through finite element analysis, significantly enhancing overall rigidity and torsional resistance. Thickened side plates and densely arranged ribs effectively prevent the bucket from deforming or cracking during intense excavation in hard rock.

3. Premium teeth and adapters: The standard heavy-duty rock teeth are cast from a special alloy steel and heat-treated for enhanced hardness and wear resistance. The reinforced adapter design provides greater support, reduces the risk of tooth root fracture, and facilitates quick replacement. 4. Dual Protection for Key Areas: Innovatively employing **wear-resistant blocks embedded in or welded onto an ultra-thick wear-resistant layer** in areas subject to the most severe wear, such as the bucket lip and side cutting edges, creates a dual protective barrier, significantly extending the service life of these "hard-hit" areas.

5. Optimized Bucket Shape and Feed Angle: The bucket shape is optimized based on fluid dynamics and digging resistance simulations to optimize the feed angle and bucket capacity curve. This ensures digging force while increasing the bucket fill rate, minimizing material slippage, and improving single-operation efficiency.

Significant Value, Visible Benefits

1. Doubled Service Life: Under comparable hard rock conditions, this bucket's service life can be 2-3 times or more longer than conventional buckets, significantly reducing spare part replacement frequency and downtime for maintenance.

2. Sharpened Operational Efficiency: Powerful rock-breaking capabilities and an optimized bucket design significantly increase material excavation volume per unit time, accelerating project progress.

3. Reduced Overall Cost: While the initial investment is slightly higher, the bucket's exceptionally long service life and reduced downtime significantly reduce unit operating costs, delivering an exceptional return on investment (ROI).

4. Enhanced Equipment Protection: The bucket's enhanced rigidity and impact resistance effectively absorb and disperse impact forces, minimizing damage to critical excavator components such as the boom and arm.

Widely applicable, the first choice for harsh working conditions

This series of rock buckets is suitable for a wide range of excavator models (from small and medium to large and extra-large). It is an ideal tool for open-pit mining (coal, metal, and stone), large-scale rock foundation excavation, tunnel portal treatment, river desilting (including hard rock), and crushing construction waste (including reinforced concrete).

Leading the Future, Continuing Innovation

We will continue to invest in R&D, focusing on user feedback from real-world applications. We will continuously optimize product performance, launch more rock bucket models to meet diverse needs, and explore new areas such as intelligent and lightweight design. Our goal is to provide more reliable and efficient rock operations solutions for the global heavy industry.

Wheel Loader

Wheel Loader  Excavator

Excavator  Motor Grader

Motor Grader  Backhoe Loader

Backhoe Loader  Road Roller

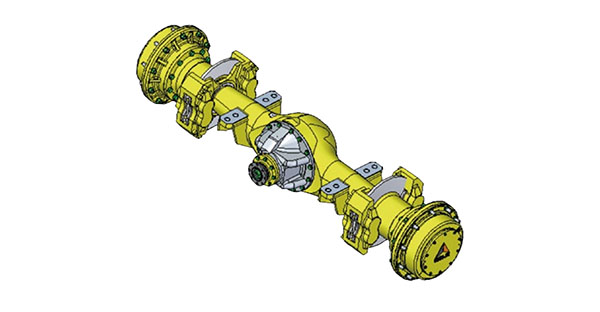

Road Roller  Spare Parts

Spare Parts