Cylinder Head Cover Gasket: Top China Suppliers & Factories Guide for Quality Parts

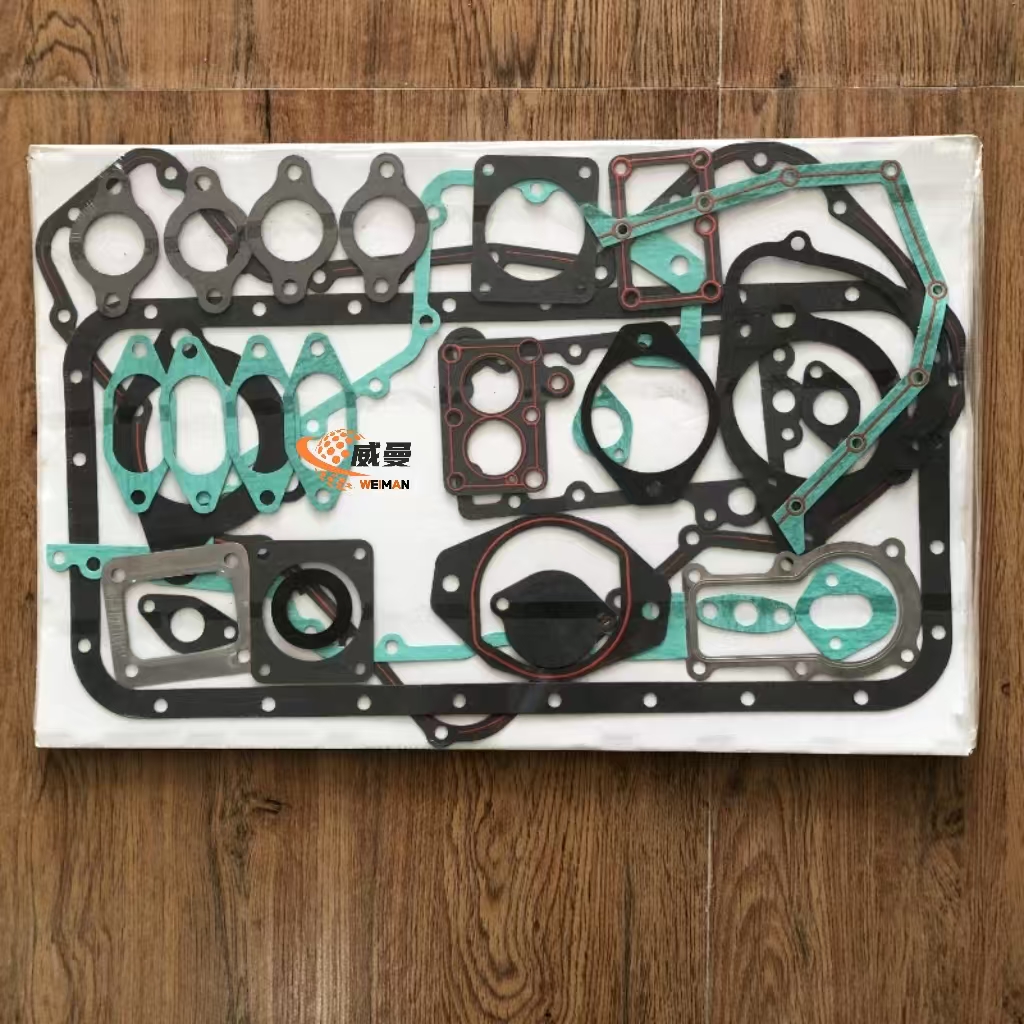

For high-quality cylinder head cover gaskets, you’ve come to the right place. Our gaskets are sourced from trusted factories in China, ensuring durability and reliability for all your automotive needs. We prioritize precision engineering, with each gasket adhering to strict quality standards. The team at Linyi Weiman Import and Export Co., LTD. is committed to excellent customer service and timely delivery tailored to your specifications. We offer competitive pricing and the capability to manage bulk orders, seamlessly supporting your business operations. Enhance your product lineup with our cylinder head cover gaskets. Whether you are a wholesaler or retailer, we are ready to forge a strong partnership that prioritizes mutual success. Contact us for samples or additional information!

10 Essential tips For Cylinder head cover gasket Manufacturers You Can Rely On Now Trending

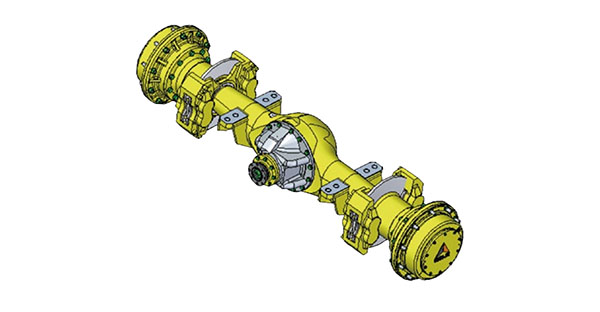

In the dynamic world of construction equipment, cylinder head cover gaskets play a crucial role in ensuring the reliability and efficiency of heavy machinery. As a leading supplier based in Linyi, Shandong Province, Weiman Import and Export Co., LTD recognizes the importance of quality components in equipment longevity and performance. Here are ten essential tips for manufacturers of cylinder head cover gaskets looking to stay relevant and appealing to global procurement markets. First, focus on material quality. Sourcing high-grade materials that withstand extreme temperatures and pressures is vital for durability. Additionally, implementing stringent quality control measures can help manufacturers meet international standards, which is preferred by buyers worldwide. Second, invest in innovative technology. Adopting advanced production techniques can enhance precision and reduce errors, leading to perfectly fitting gaskets that ensure optimal performance. Third, prioritize customization. Offering a range of gasket sizes and compositions can cater to diverse machinery, from wheel loaders to excavators, expanding your market reach. Lastly, build reliable partnerships. Collaborating with top construction equipment suppliers like Weiman can increase your visibility and credibility in the industry. Emphasizing excellent customer service and timely deliveries will foster trust and long-term relationships with global buyers. By following these essential tips, cylinder head cover gasket manufacturers can not only improve their products but also enhance their competitive edge in the international market.

10 Essential Tips For Cylinder Head Cover Gasket Manufacturers You Can Rely On Now Trending

| Tip No. | Tip Description | Importance Level | Implementation Difficulty | Current Trend |

|---|---|---|---|---|

| 1 | Use High-Quality Materials | High | Medium | Trending |

| 2 | Implement Rigorous Quality Control | Critical | High | Emerging |

| 3 | Invest in Technology and Equipment | High | High | Trending |

| 4 | Enhance Customer Service | Moderate | Low | On the Rise |

| 5 | Focus on Sustainable Practices | High | Medium | Suggested |

| 6 | Strengthen Supplier Relationships | Moderate | Low | Increasing |

| 7 | Train Your Workforce | Critical | Medium | Trending |

| 8 | Regularly Update Designs | High | Medium | In Demand |

| 9 | Monitor Market Trends | Moderate | Low | Essential |

| 10 | Ensure Compliance with Regulations | Critical | High | Mandatory |

Why Invest In Cylinder head cover gasket Guarantees Peak Performance Is The Best

M

Michael Anderson

The product quality is outstanding! I appreciate the responsive after-sales service, which made my experience seamless.

25 May 2025

A

Ava Martinez

Great product! After-sales team showed true professionalism and helped with all my queries.

12 May 2025

D

Daniel Young

Really pleased with the durability of this product! The support staff was very professional.

26 May 2025

I

Isaac Hayes

Quality exceeds expectations! The support team handled my inquiries with professionalism.

09 June 2025

L

Layla Carter

Remarkable item! The support team was responsive and extremely professional.

18 May 2025

M

Maya Rivera

Absolutely love this product! The after-sales service resolved my concerns quickly.

04 July 2025

Wheel Loader

Wheel Loader  Excavator

Excavator  Motor Grader

Motor Grader  Backhoe Loader

Backhoe Loader  Road Roller

Road Roller  Spare Parts

Spare Parts